Making a Didgeridoo

Learn how to make your own Didgeridoo with Didge in a Day. We have been handcrafting high end, musical quality didgeridoos since the year 2000, with a focus on musical quality and professional craftsmanship. The following resource is taken directly from the Echo Tree website, www.echotree.com.au.

Technical info

Clear bass and a sharp 'edge' are two attributes that Echo Tree's didgeridoos are known for. One of the reasons for this is because of the timber we use. This timber is extremely dense; denser than Ironbark in fact, one of Australia's well known, hard native timbers. Because of this we continue to use arid grown 'Greybox' to craft many of our didgeridoos. The extreme density of this timber largely contributes to the great 'edge' our instruments produce. We of course do not exclude the use of other timber types in our hancrafting process.

Didgeridoo Collection

Echo Tree only make their didgeridoos from sound, good quality Australian timbers that have been naturally hollowed out by termites. These timbers are collected by Echo Tree.

Once we have selected our didgeridoo, the next step is to clean the termite waste from the inside of the hollow tree.

Didgeridoo Seasoning

After the hollow tree has been cleaned out we place it under controlled conditions to season. With the bark still on, we leave our timber to season, before it is ready for the didgeridoo handcrafting process.

Technical info

The main reason that many didgeridoos crack and split after purchase is that they are made from timber that is 'green' or unseasoned. Green timber is very unstable and as it dries out in uncontrolled conditions it will often split. Another reason many didgeridoos fail a short time after purchase is because they are not properly treated and sealed. A didgeridoo made from unseasoned, untreated and unsealed timber can still legitimately be called 'genuine' or 'authentic' but will not necessarily be of a high quality standard.

The Handcrafting Process

The handcrafting process is now ready to begin. Starting with a coarse sand paper and working down to a very fine grade, the didgeridoo is sanded back to reveal the beautiful native Australian wood grain that lies beneath.

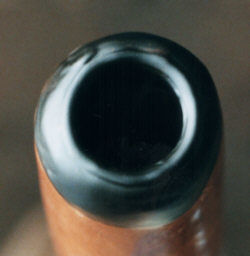

Once we have our instrument at this stage, the Echo Tree emblem is etched into the timber. The emblem is located on the back of the didgeridoo near the base. A serial number is also burnt into the wood, just beneath the emblem, and because we accurately key all our instruments, the muscal note of the didgeridoo is also burnt into the inside of the bell end.

Technical info

We choose not to use 'dowels' or wooden 'plugs' to seal imperfections in our instruments. The rate of expansion of a dowel will always be different to that of the side grain of a didgeridoo. This will result in failure of the integrity of the instrument.

Echo Tree starts with premium raw materials and this is another reason why our finished product is such high quality.

Outside Finish

The instrument is then sealed both inside and out. We seal the inside to protect it from the moisture and humidity that results from a player's breath and dribble. If the inside is not sealed, the constant hydration and dehydration (wetting and drying) that will occur with use can age and crack the instrument from the inside out. This can eventually lead to air leaks and the need for costly repair.

The outside is sealed for similar reasons but with the added function to enhance the beauty of the wood grain and/or Aboriginal artwork it protects

Technical info

The outside is sealed to protect the instrument from humidity, temperature changes, moisture, contaminants (e.g. from the skin), sunlight and mild mechanical damage. Because we place a guarantee on all our didgeridoos it is imperative to us that we are able to present them to the buyer in perfect condition.

Didgeridoo Mouthpiece

In the final stages of our handcrafting process we hand mold a wax or wooden mouthpiece, test it for 'playability' and then key the instrument. The 'key' or note of the didgeridoo is important for its compatibility when played with other musical instruments.

Because we offer both wood grain and painted instruments, we now select which ones are to be sent to Aboriginal artists.

Didgeridoo Artwork

All Aboriginal artwork that appears on an Echo Tree didgeridoo is a unique hand painted indigenous creation.

Once artwork has been hand painted onto the instrument, a number of further protective layers are applied to enhance and protect the artwork. Finally we execute an extensive quality control check and test the musical quality of each didgeridoo.

At this stage we also set our prices according to sound quality, artwork, shape, aesthetics, etc.